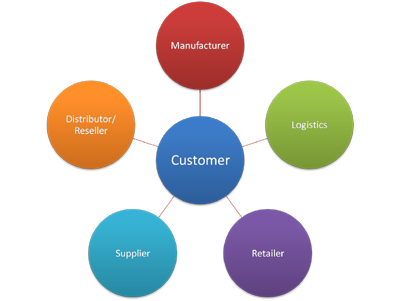

Supply Chain Management (SCM), including among all Warehouse Management and Inventory Management, is the management of services and products that are to be delivered to customers.

Supply Chain Management includes everything from storage and all movements of the products and all all parts contained in the products, including all work processes performed to get the products from the point of creation to the end-point.

This is why we see warehouse management and inventory management in the supply chain management area. Warehouse management is aimed to control storage and movements of material in a warehouse, including how to pick material and make sure that the right material is packaged for the right customer.

Inventory management is the control of how much you have stored to know what is available for distribution to customers.

Inventory management is the control of how much you have stored to know what is available for distribution to customers.

To help with keeping the supply chain management in control you have Supply Chain Management Software which can also be divided into different systems, such as Inventory Management Systems and Warehouse Management Systems.

A Warehouse Management System, also called WMS, is helping you to store the materials in the correct place in the warehouse in the right place and keeps track of when you are moving them. A commonly used tool to help with moving material is the hand terminal. When picking the material you will then scan the material barcode, including all specifics such as type, color, etc, and make sure that the right information of what is stored in the warehouse is recorded. This will also help in making sure that the customer receives what is ordered.

An Inventory Management Systems help you to keep control over how much you have in stock so that you have the correct amount of products in stock according to what the demand is. By having good control over the inventory you make sure that the customer will quickly get what is ordered and will also make sure that you get the correct amount of stock not to be over-stocked.

Every now and then you control the inventory, count all products in stock, to make sure that the information in the inventory management system is correct.

Every now and then you control the inventory, count all products in stock, to make sure that the information in the inventory management system is correct.

A Supply Chain Management Software (SCMS) often includes the two above mentioned systems and some more functionality to have good control over the flow of products and services. One important functionality is the forecasting functionality to understand how the future will look and therefore be able to order correct amount of products to have in stock. It is also important to be able to integrate the supply chain management system with other systems, including the systems at the suppliers. All to minimize the lead times.

Supply Chain Management Systems are vital for suppliers of products. The bigger organization and therefore the more products in circulation, the more important with more complex and intelligent systems. When implementing the supply chain management system you will quickly realise that the expectations on the future is often very unrealistic. Using information of the past and the trends that have been, the supply chain management systems will help you a lot in keeping better control of how much products you need to order to have a smooth product flow, both from the suppliers and to the customers. It will not only make it possible to control the product flow but also control the resources needed from time to time to make sure that the movements of products are made correctly.

No comments:

Post a Comment